Your commercial truck inspection is crucial to the longevity of your vehicles.

Frequent, careful inspections safeguard your clients, fleet, and even your bottom line.

Sadly, because many truck rental businesses aren’t religious about their inspections, they miss out on the benefits of having well-maintained trucks.

Even small compromises in a truck inspection over time can lead to catastrophic repercussions, such as accidents, financial, and client losses, etc.

Prevent these from happening to your truck rental company. Learn the commercial truck inspection mistakes you should avoid and the right steps you should do instead.

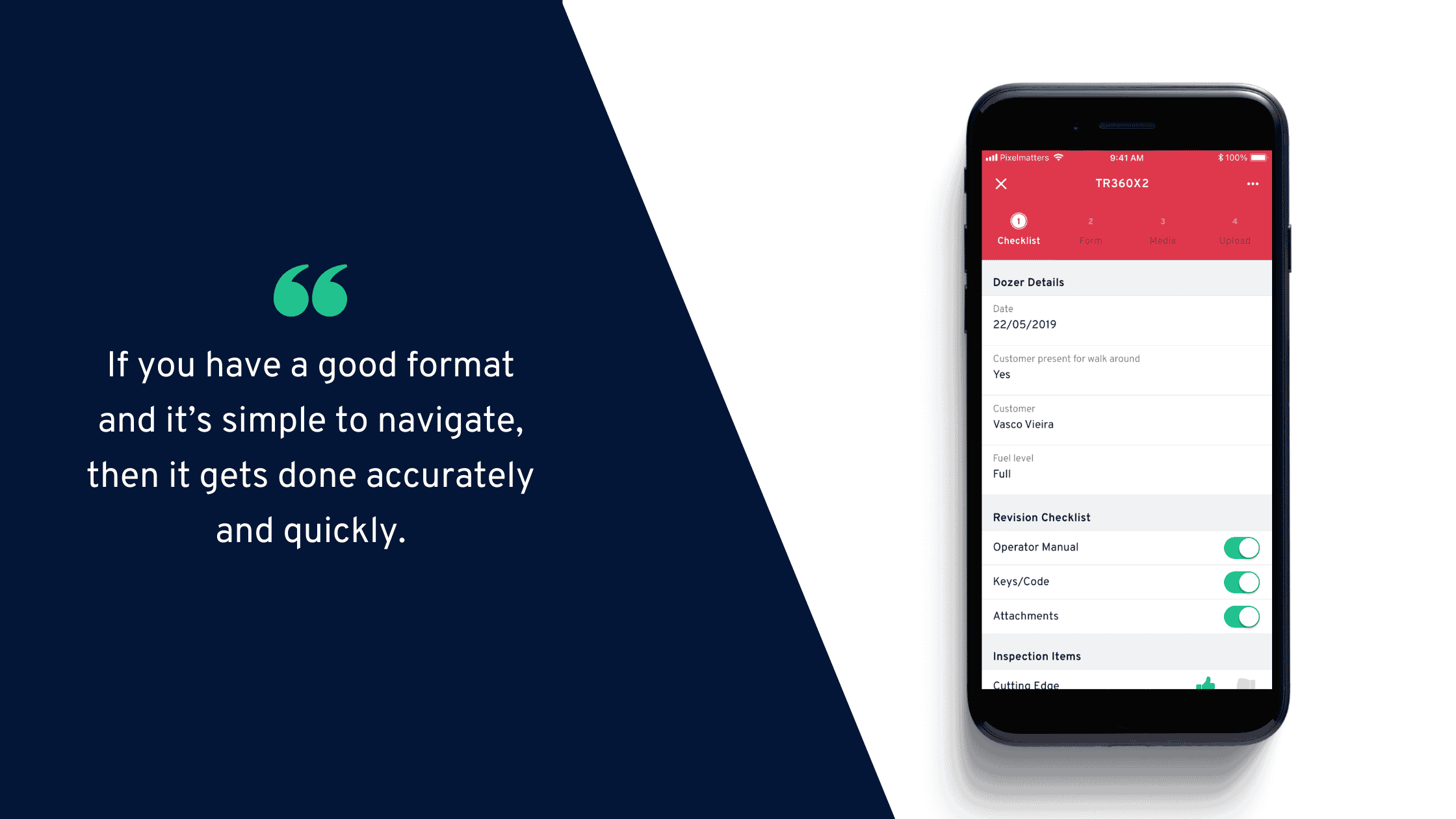

1. Superficially checking truck parts

A truck inspection often becomes so habitual that technicians can perform it mindlessly. However, this results in careless assessments of vehicle parts’ conditions that don’t guarantee safe, optimal operation.

For example, testing the braking systems requires exhaustive scrutiny. It involves checking the slack adjuster with the brakes, hunching under the trailer or over the wheels, ensuring air lines are not leaking, etc.

If your technicians carry pens and clipboards, the steps become extra tedious, wearying technicians and tempting them to dismiss careful inspection.

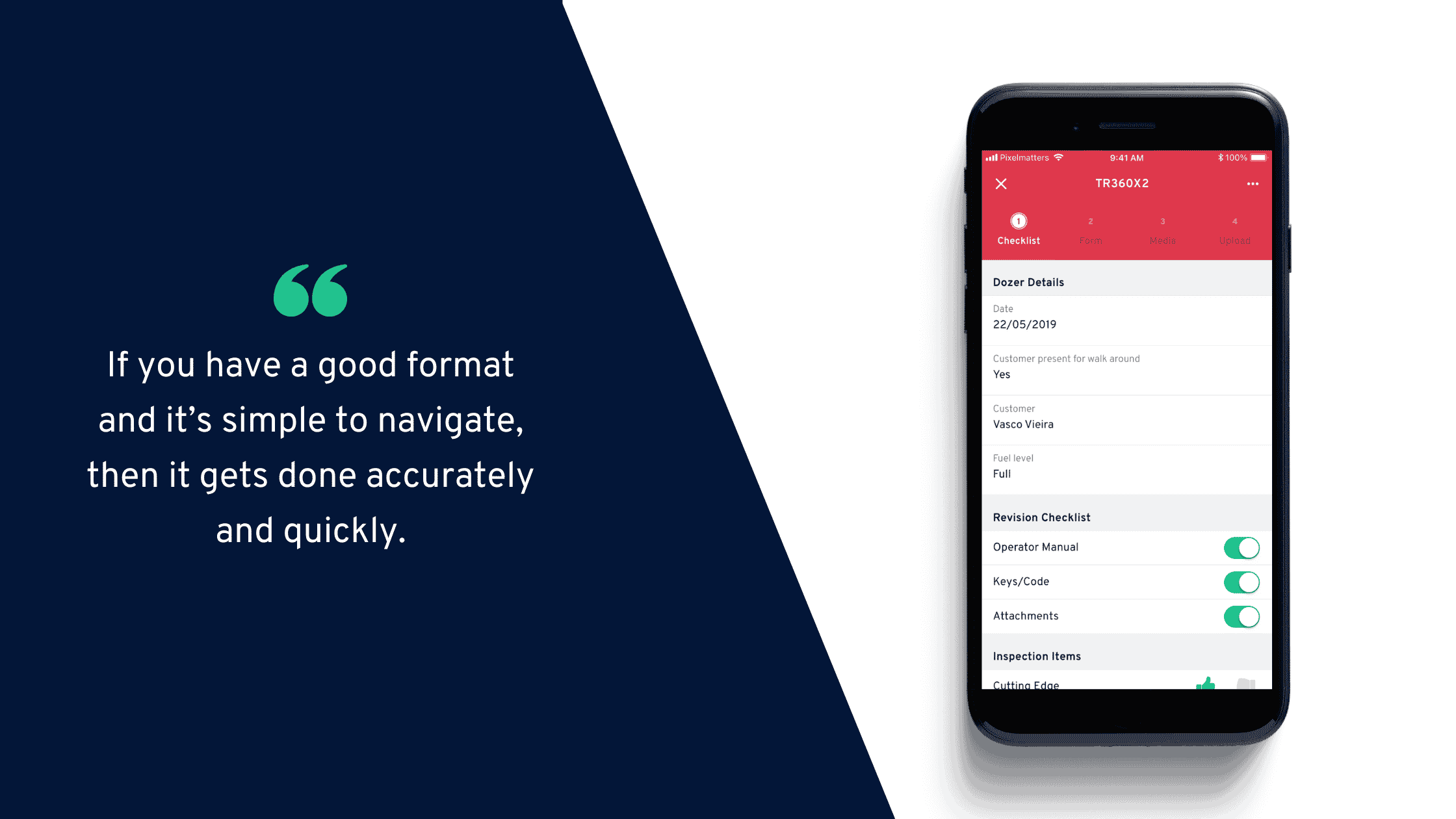

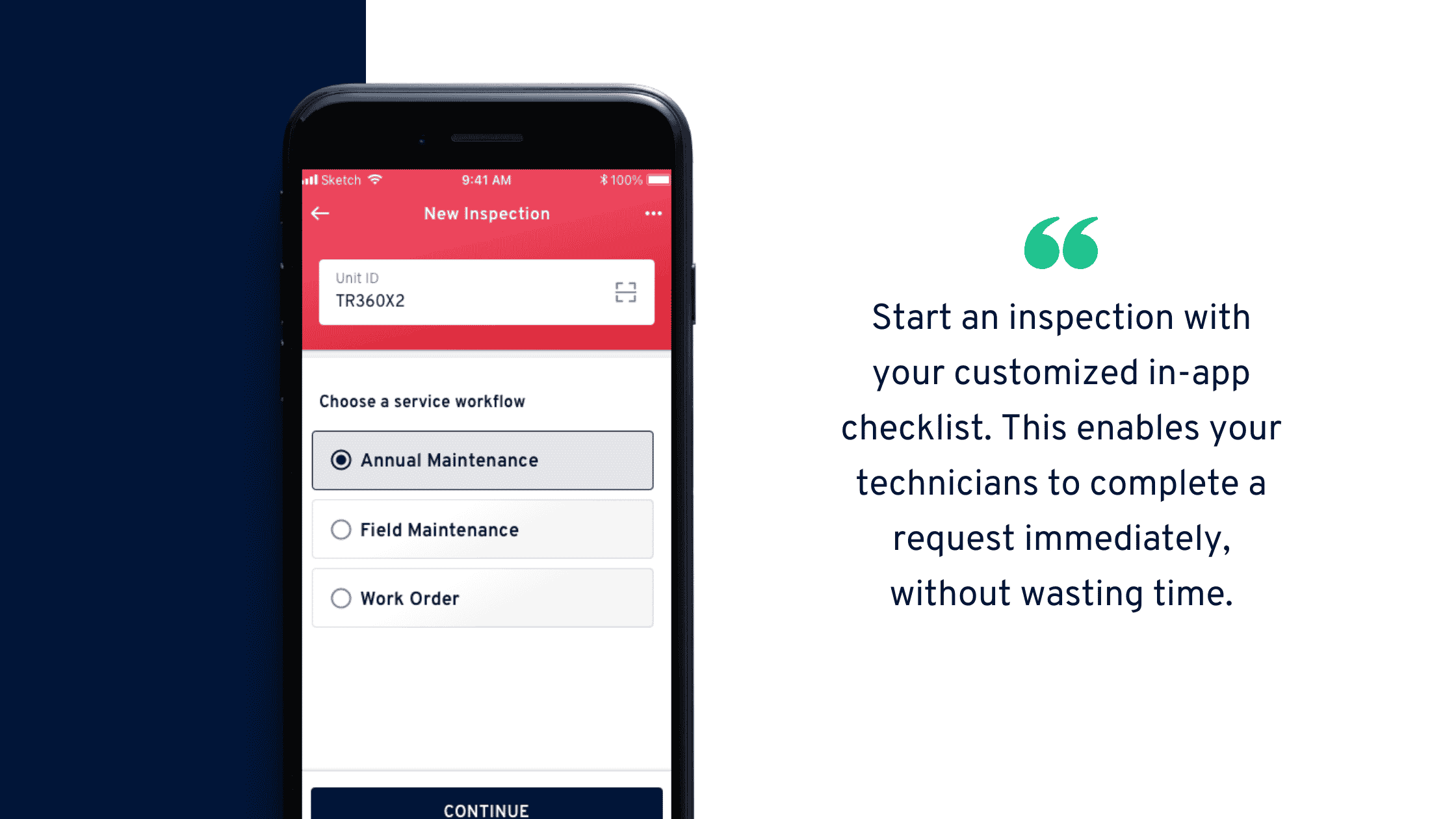

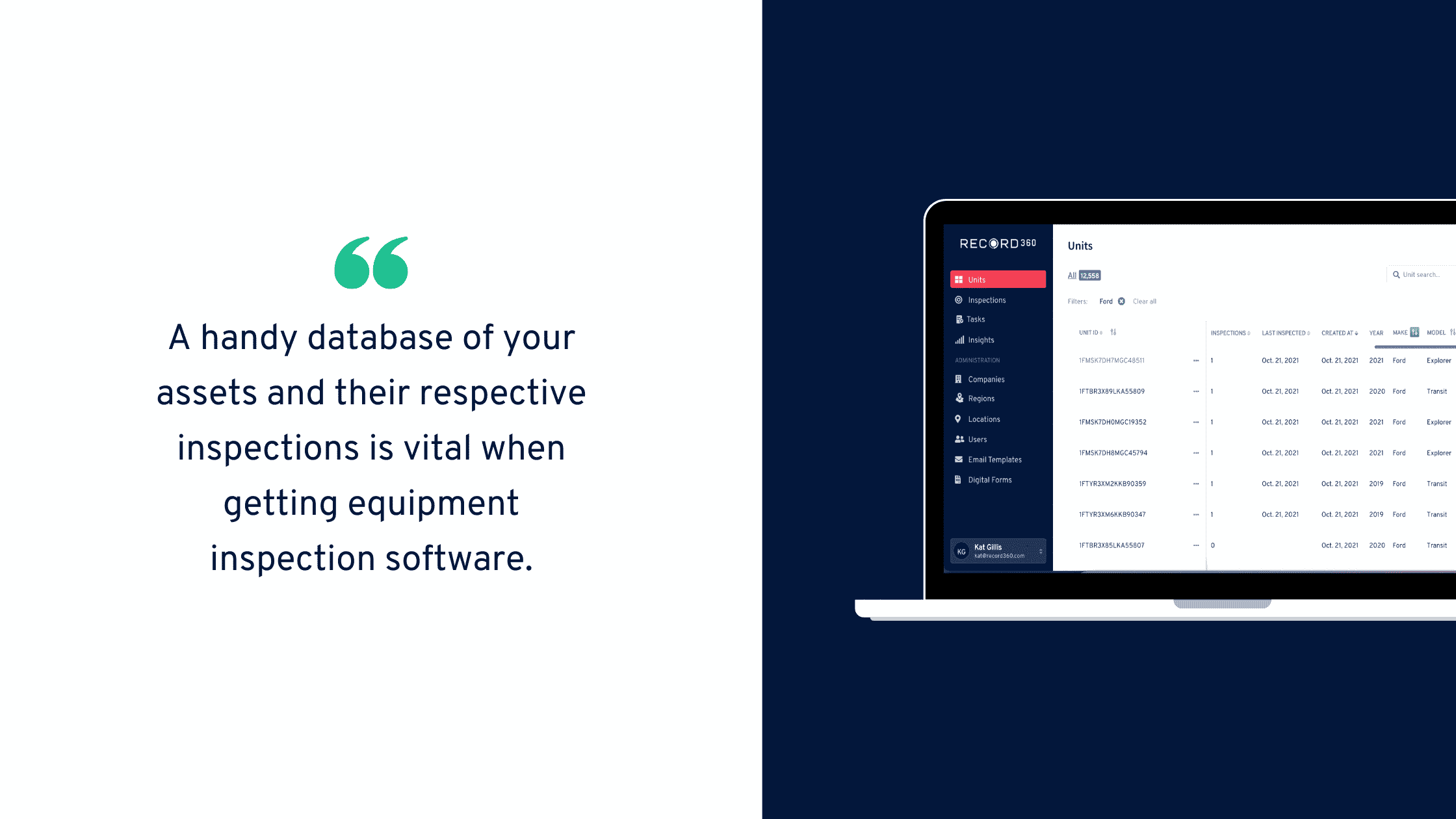

To avoid that mistake, use a digital truck inspection form. For example, our Record360 app has an electronic inspection checklist customizable according to your operations.

It even lets you capture all needed inspection data in one standard format. This makes checklists and later reports look clean and easy to read.

By loading inspection checklists onto mobile devices, technicians can painlessly carry them around while comprehensively examining your truck’s parts.

The result is a precise inspection, leading to optimally running vehicles, plus client safety.

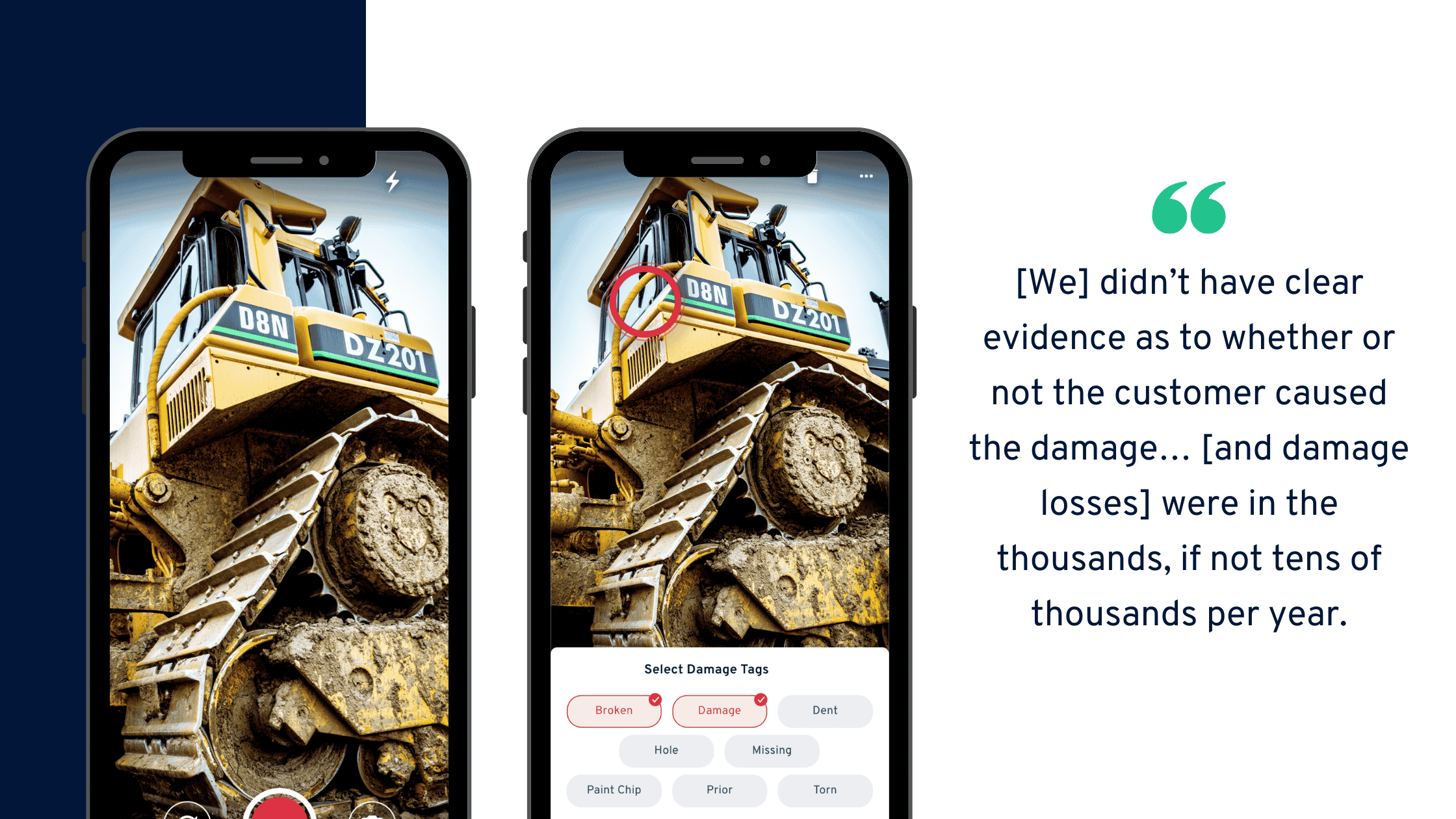

2. Inaccurate documentation of truck conditions

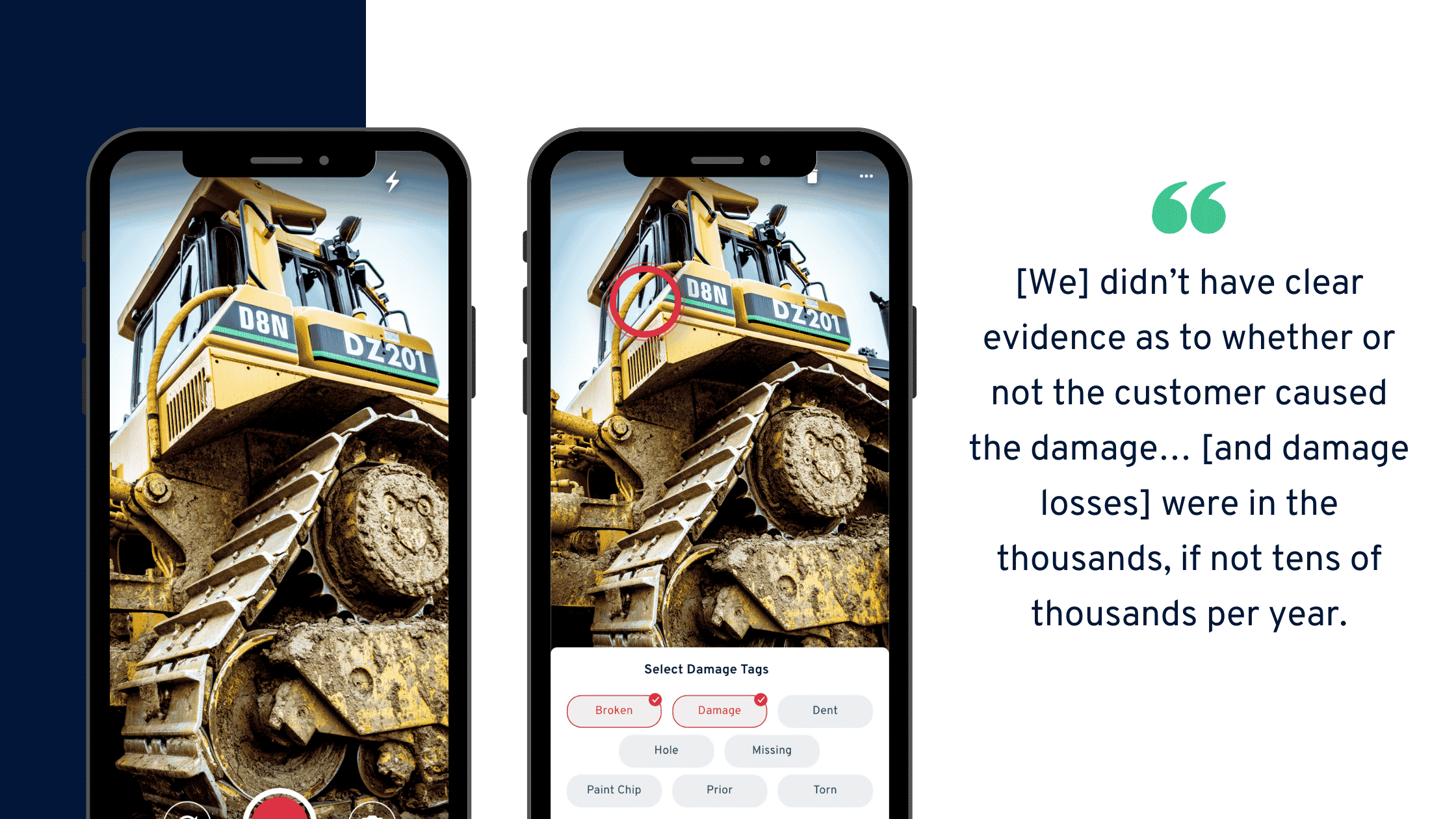

Another truck inspection mistake to avoid is using inefficient methods to record your vehicle’s pre- and post-rental conditions — especially when defects are present.

Manual methods (e.g., narrative descriptions, hand-drawn illustrations) fail to capture the extent of any damage accurately, even for visible ones.

Once you discover any defect emerging or worsening and argue with your clients about it, you’re likely to lose the dispute.

After all, you don’t have solid evidence showing they caused it.

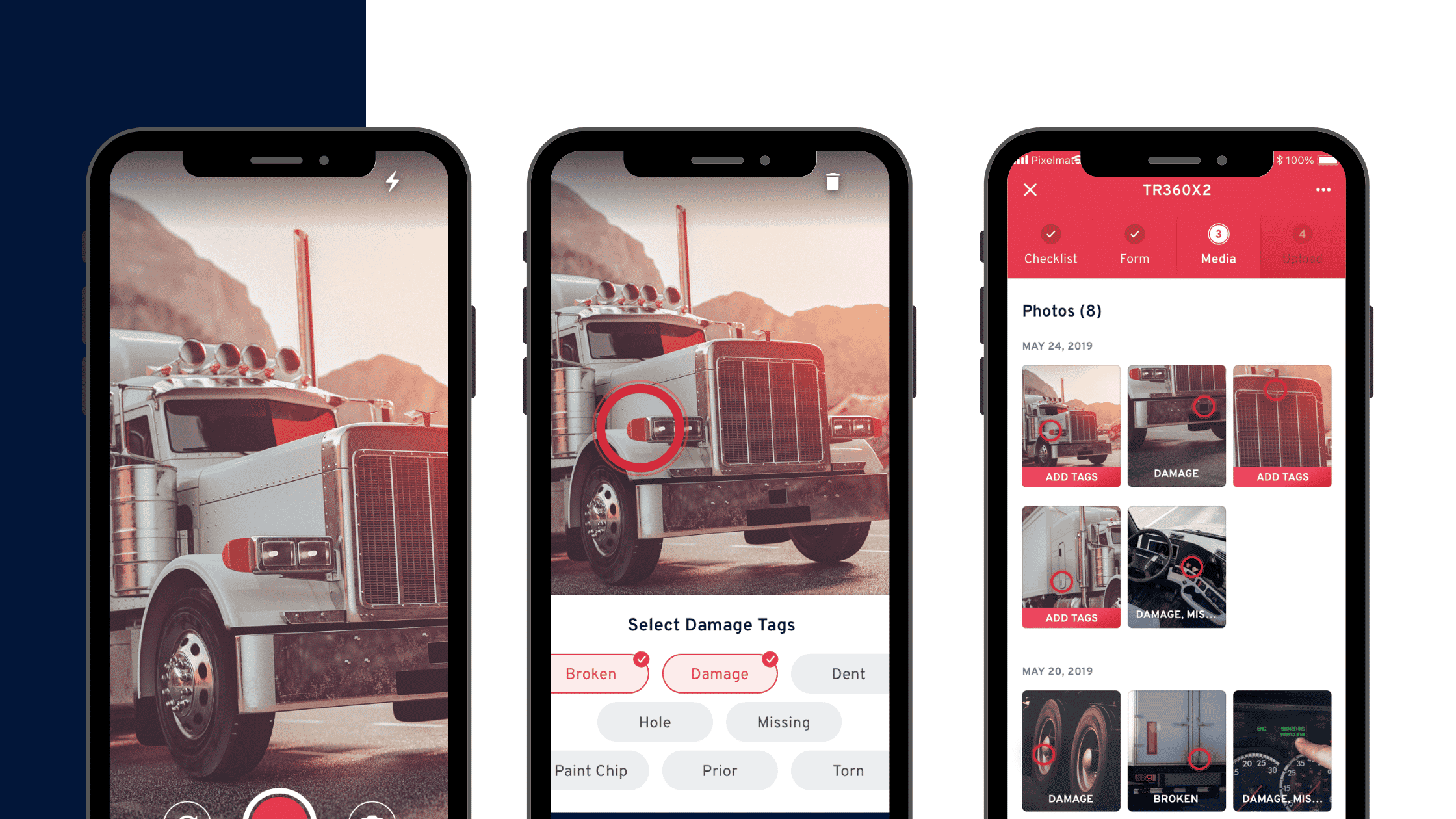

That is why, to avoid making this mistake, you must use photo and video documentation for your pre- and post-rental commercial truck inspections.

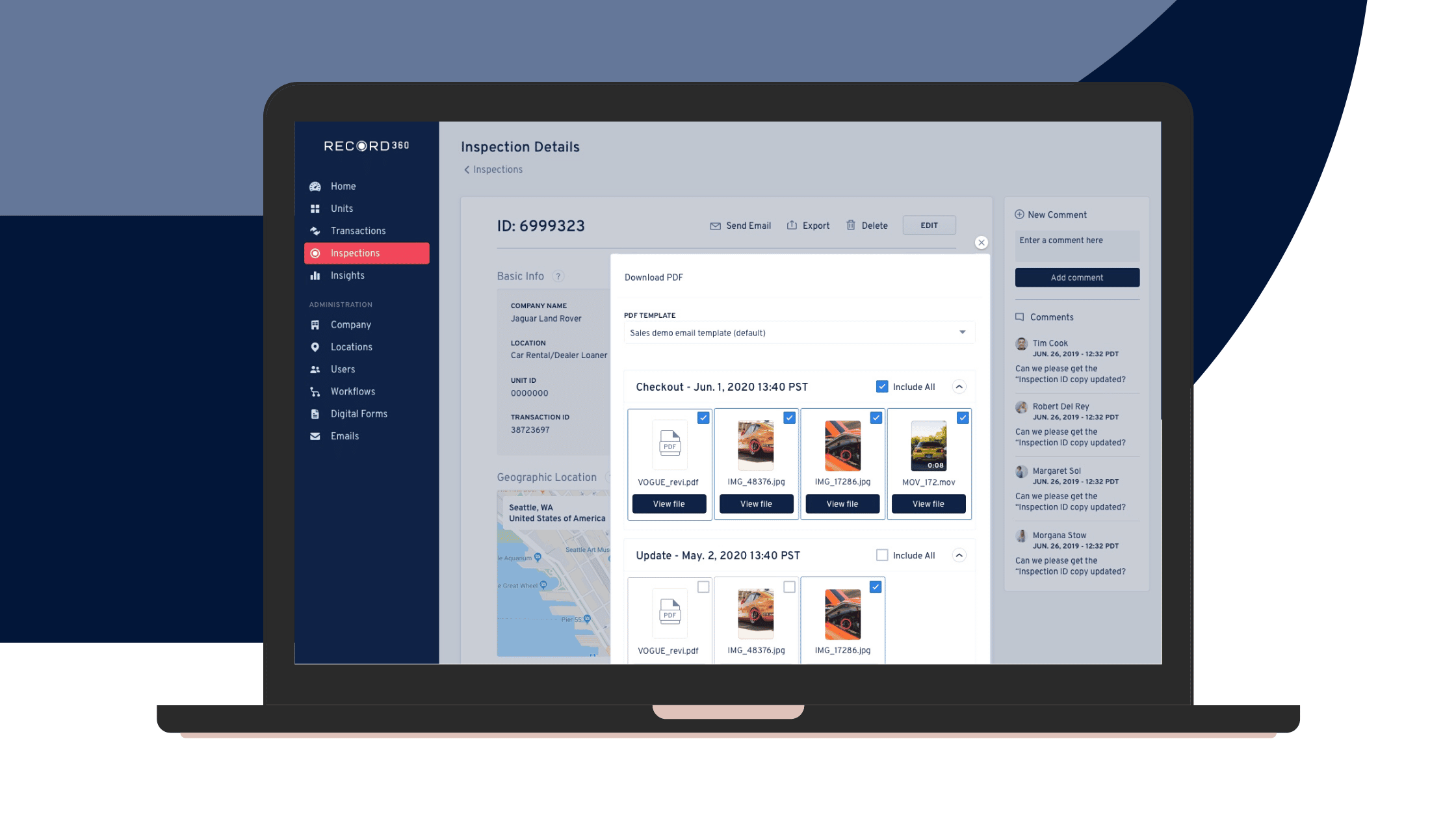

Our Record360 app demonstrates that with its high-resolution photo and video capture functionalities. It also lets you add tags indicating exactly the damage type and area in your truck.

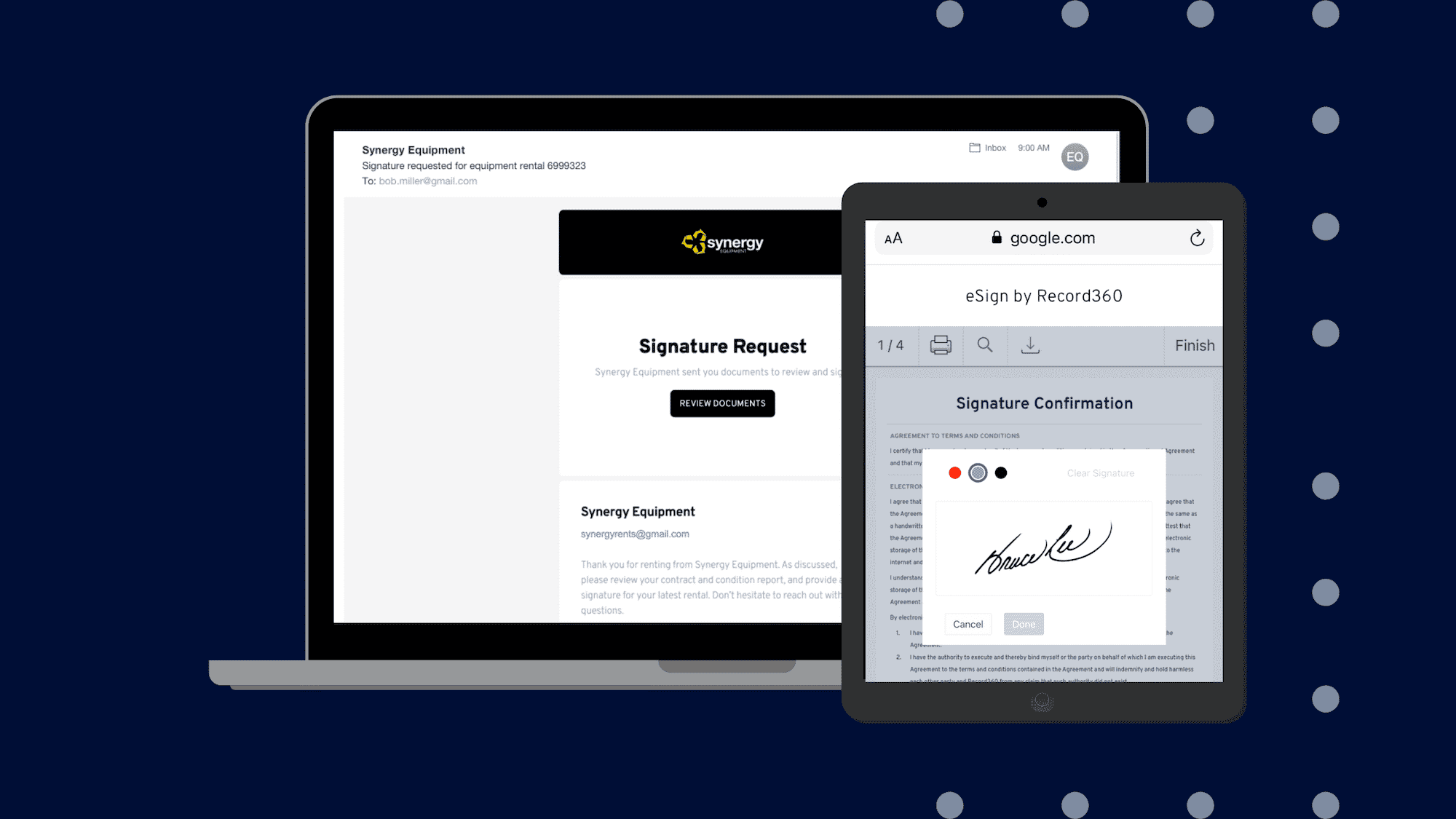

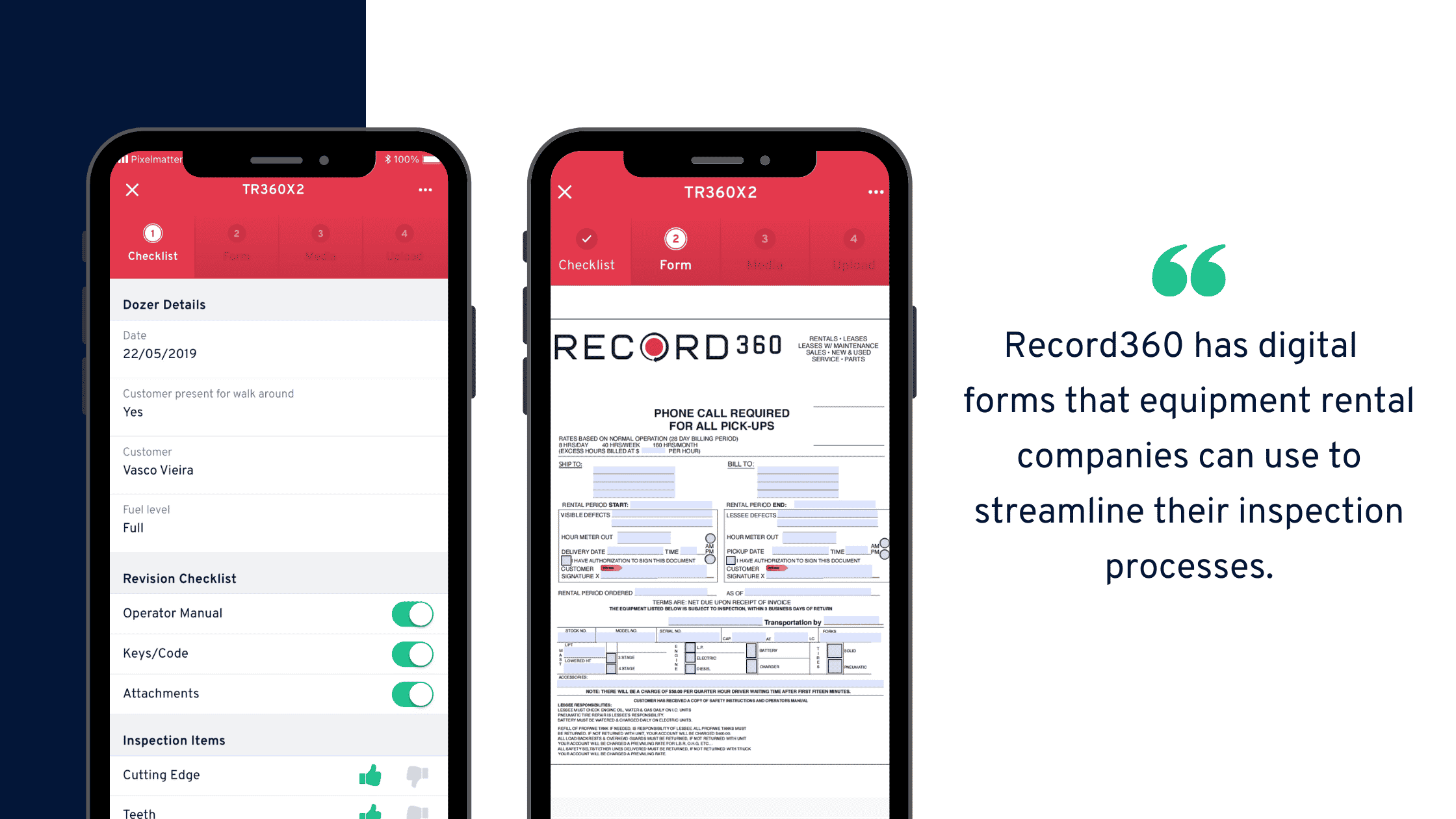

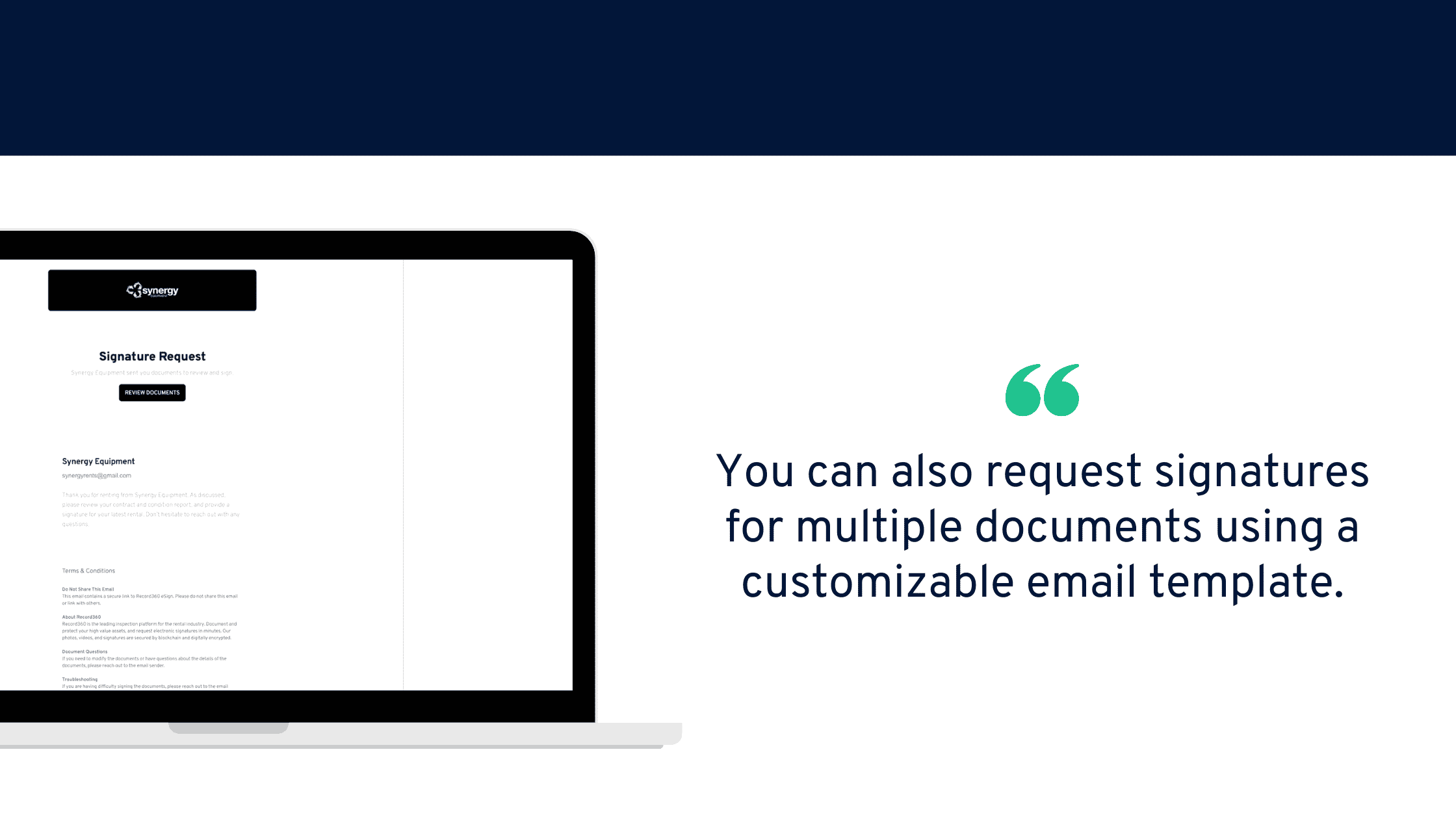

Here’s another benefit to the Record360 app for recording inspections. You can create digital pre- and post-inspection forms and reports, attach photos and videos of your truck’s condition, and request clients to verify them with their digital signatures.

All this streamlines and bolsters your documentation workflow and enables you to resolve any arising customer disputes peacefully.

3. Failing to alert the team of recorded damages

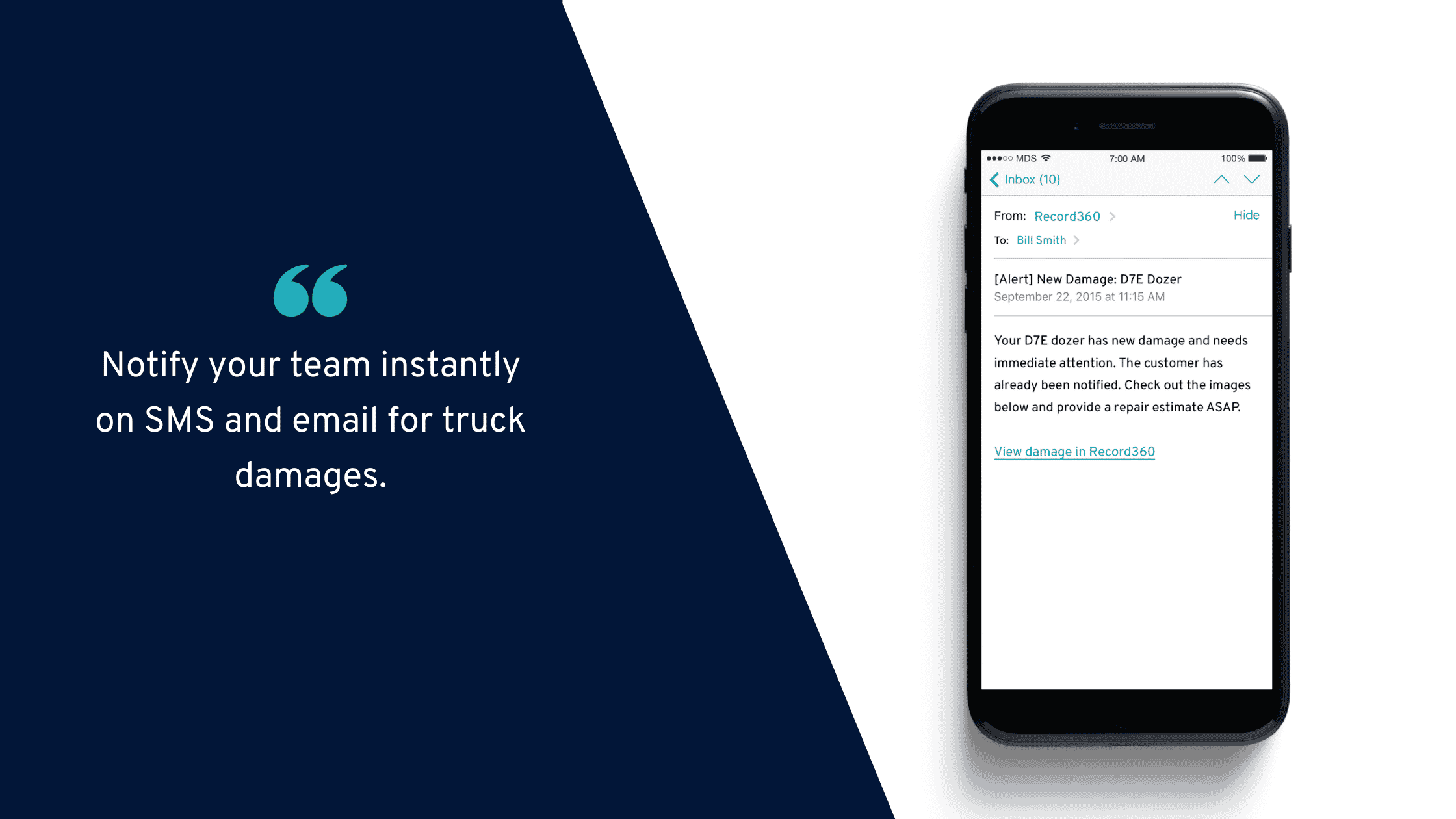

It’s not enough to document your truck’s condition properly. You should also report the damages and notify your team promptly for corrective action.

When this happens, don’t put handwritten reports on tables and risk losing them or delaying the needed repairs.

Use more efficient methods such as instant email and SMS alerts.

The Record360 app offers those features when you discover truck defects and inspections fail.

It schedules the automatic delivery of these messages, shortening the communication process from technicians to maintenance officers.

Plus, remember the photos and videos with damage tags?

Our app lets you upload them to the cloud for your team’s ready access. This enables them to view the defects even remotely and determine and schedule the correct repairs fast.

There is no need to transfer media files via USB cords and email long threads, resulting in more working time consumed and communication disarray.

4. Segregated monitoring of inspection activities

Trucking companies with multiple branches usually struggle with efficiently monitoring inspection activities from other locations. This is typical, especially if they use manual systems.

If that’s your case, you make the mistake of segregating your inspection monitoring.

This leads to inaccurate overviews of your fleet’s real situation, low responsiveness to issues, etc. Eventually, these will hurt your business performance.

The solution? Harmonize your inspection activities from various locations with truck fleet management apps.

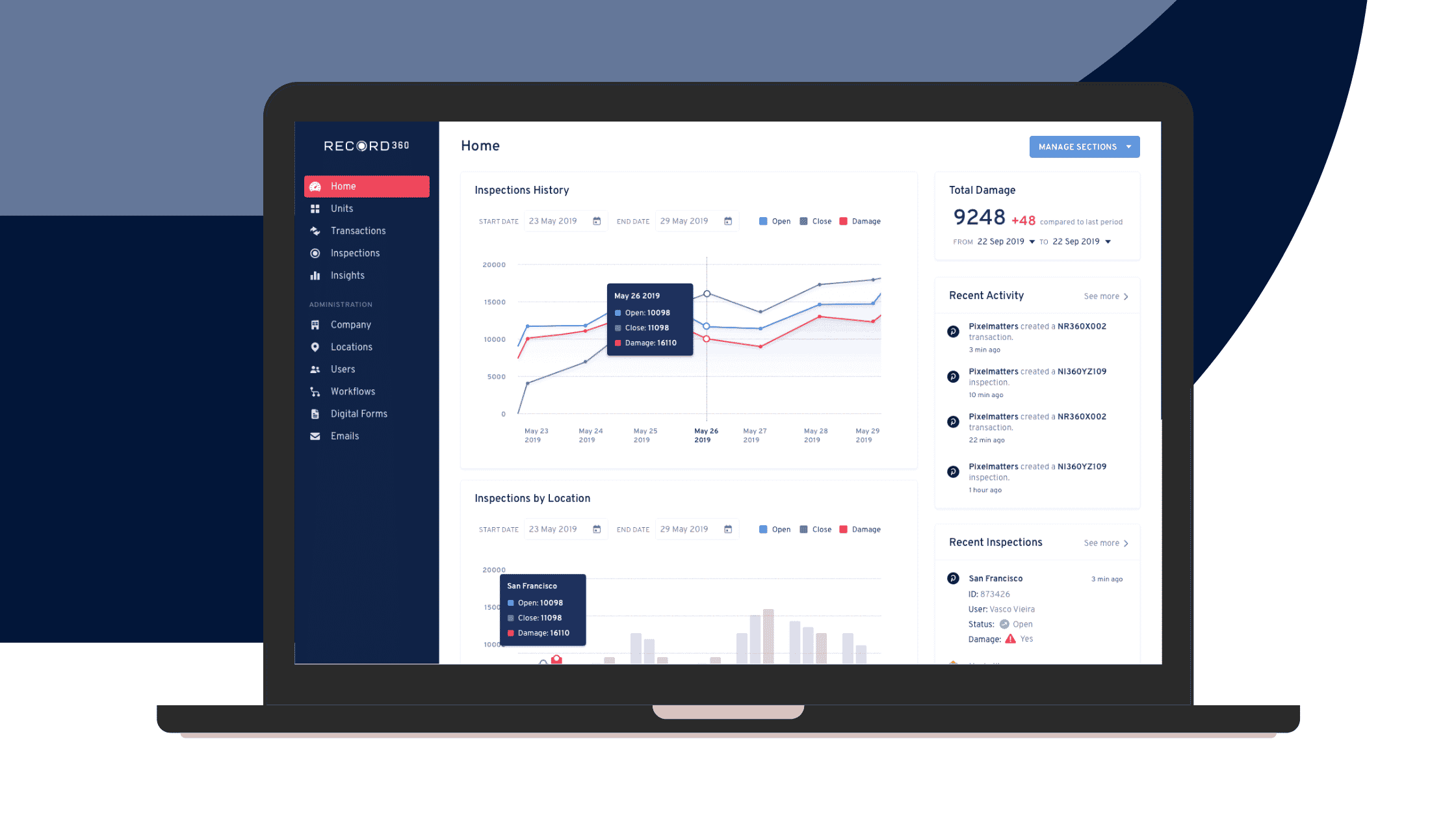

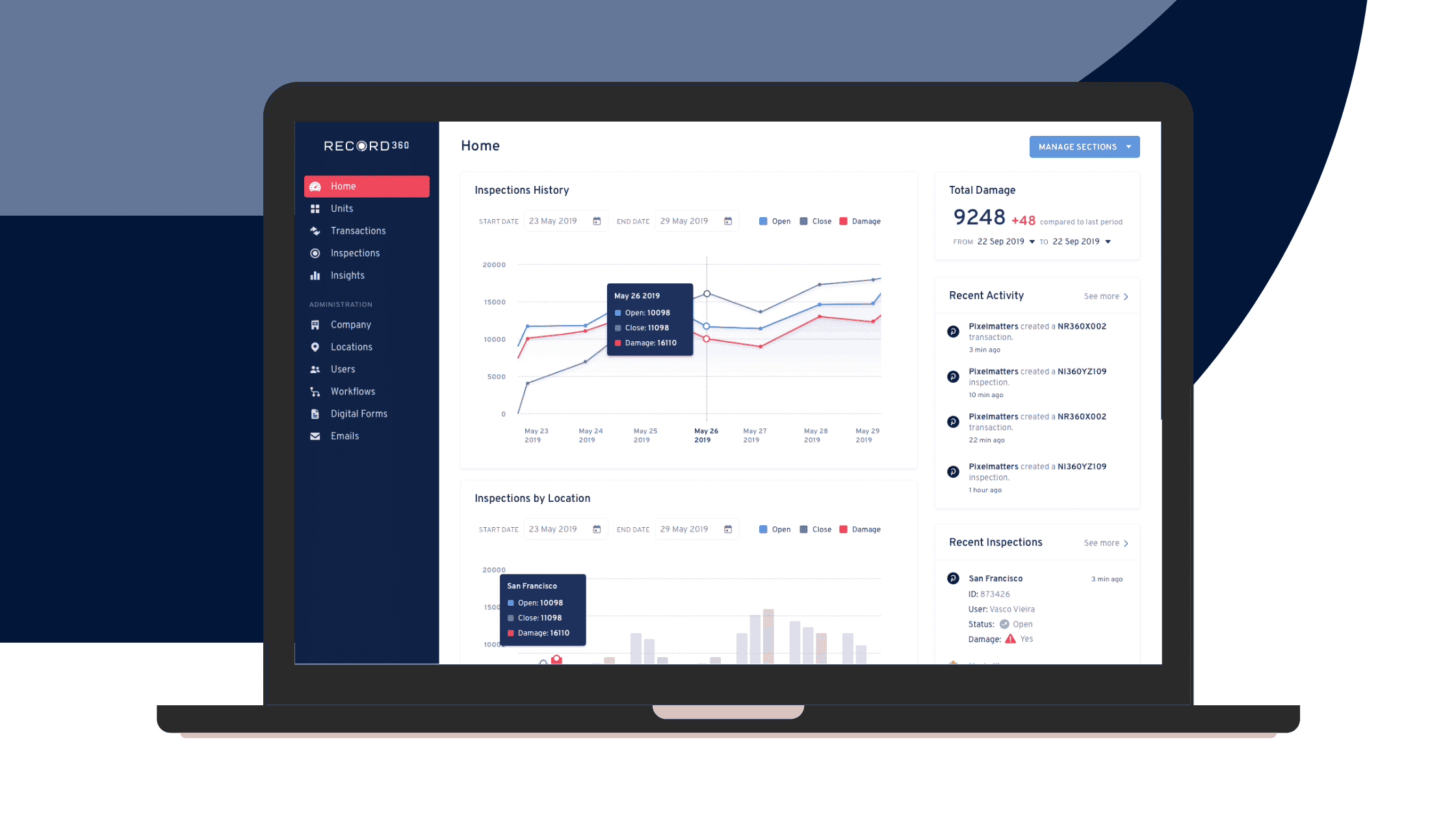

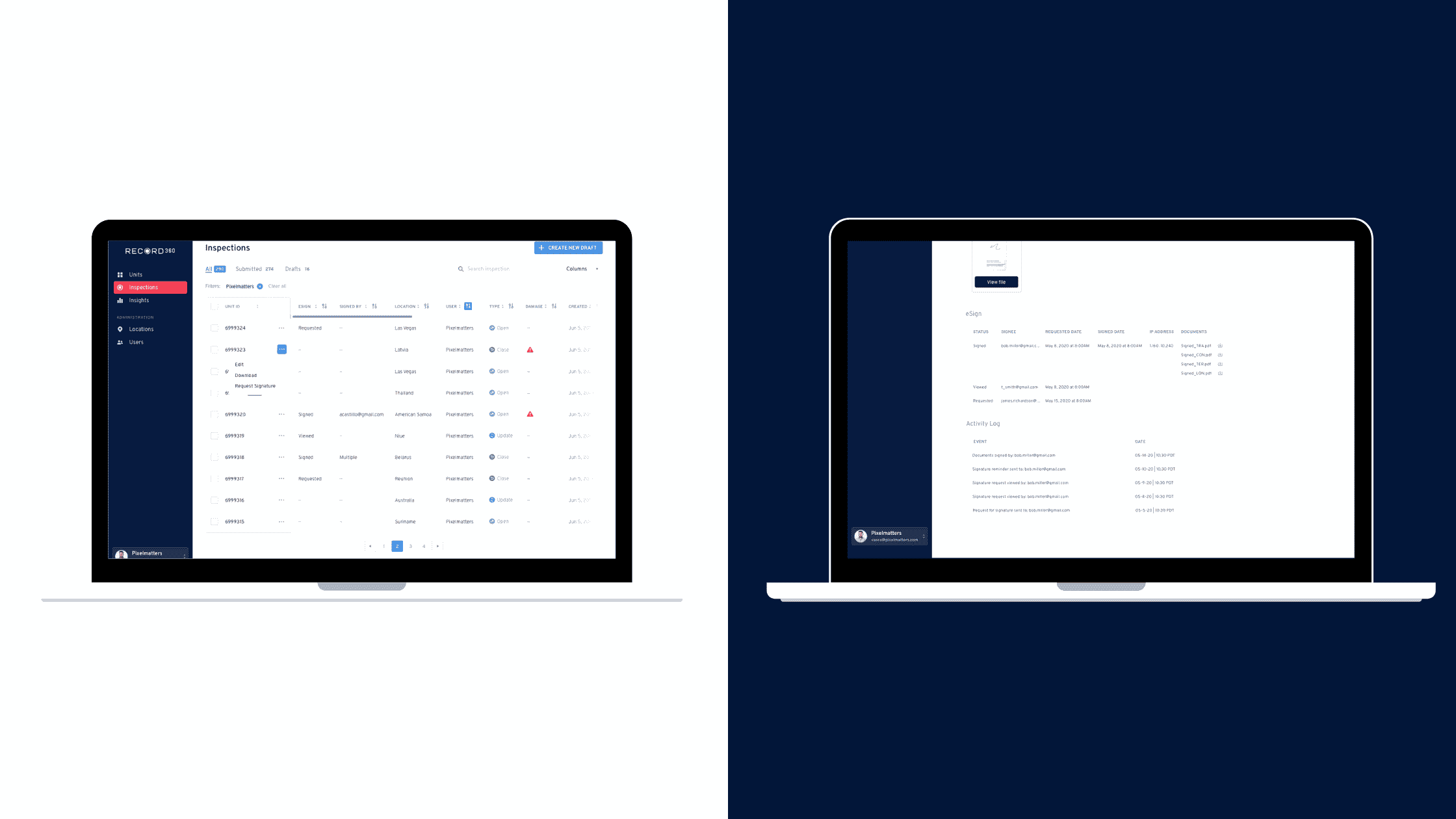

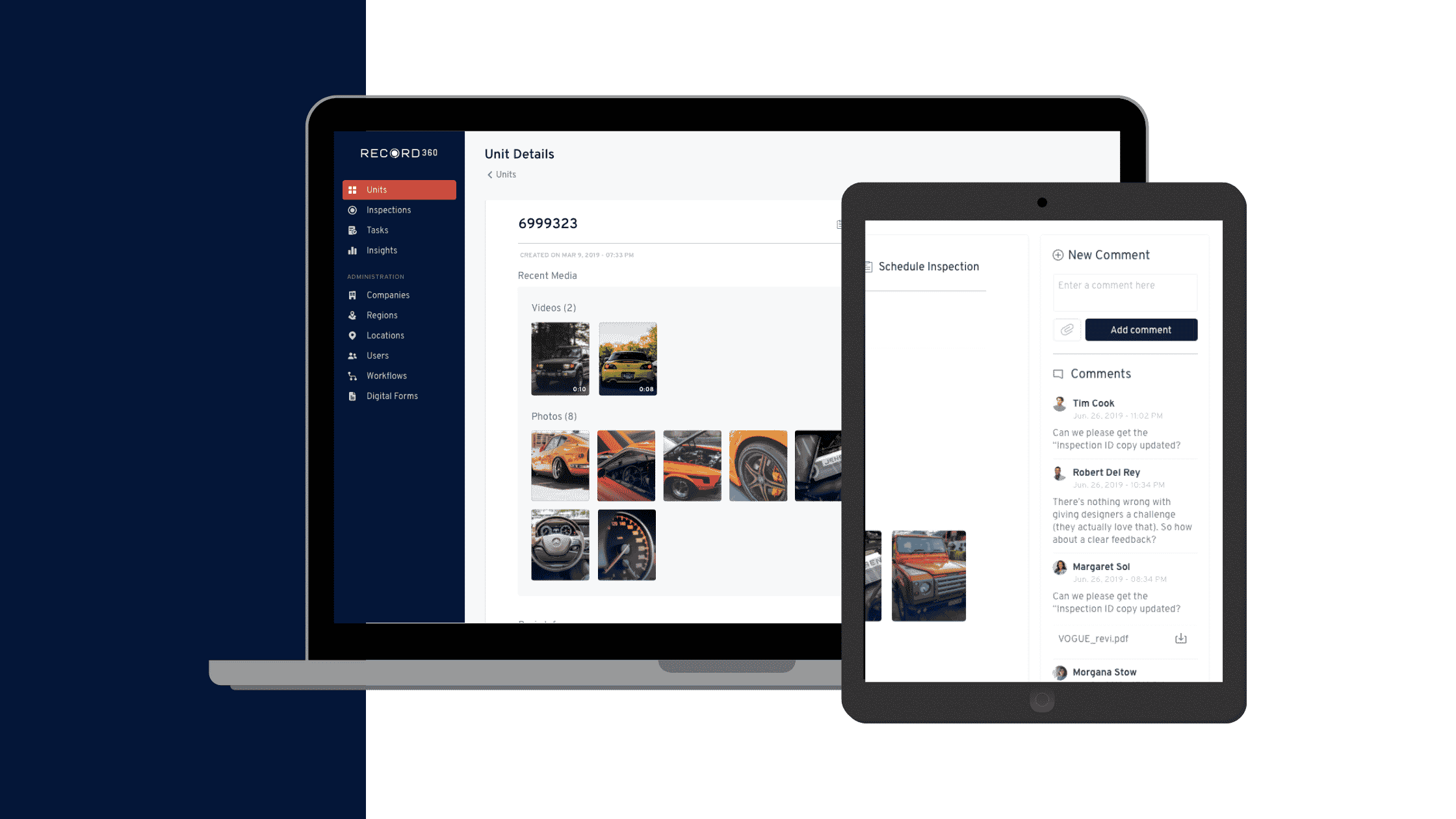

Record360 software can help you with streamlining and centralizing your inspections.

It has a user-friendly dashboard that reports your inspections by location, their history, total damages found, recent real-time activities (including vehicle checks), and more.

Moreover, if you need specific inspection data from technicians in remote locations, you can send them a direct link to our Record360 app.

You can then get instant access to that dataset and respond immediately to damage or any other issue. This feature lets you perform truck inspections from any place.

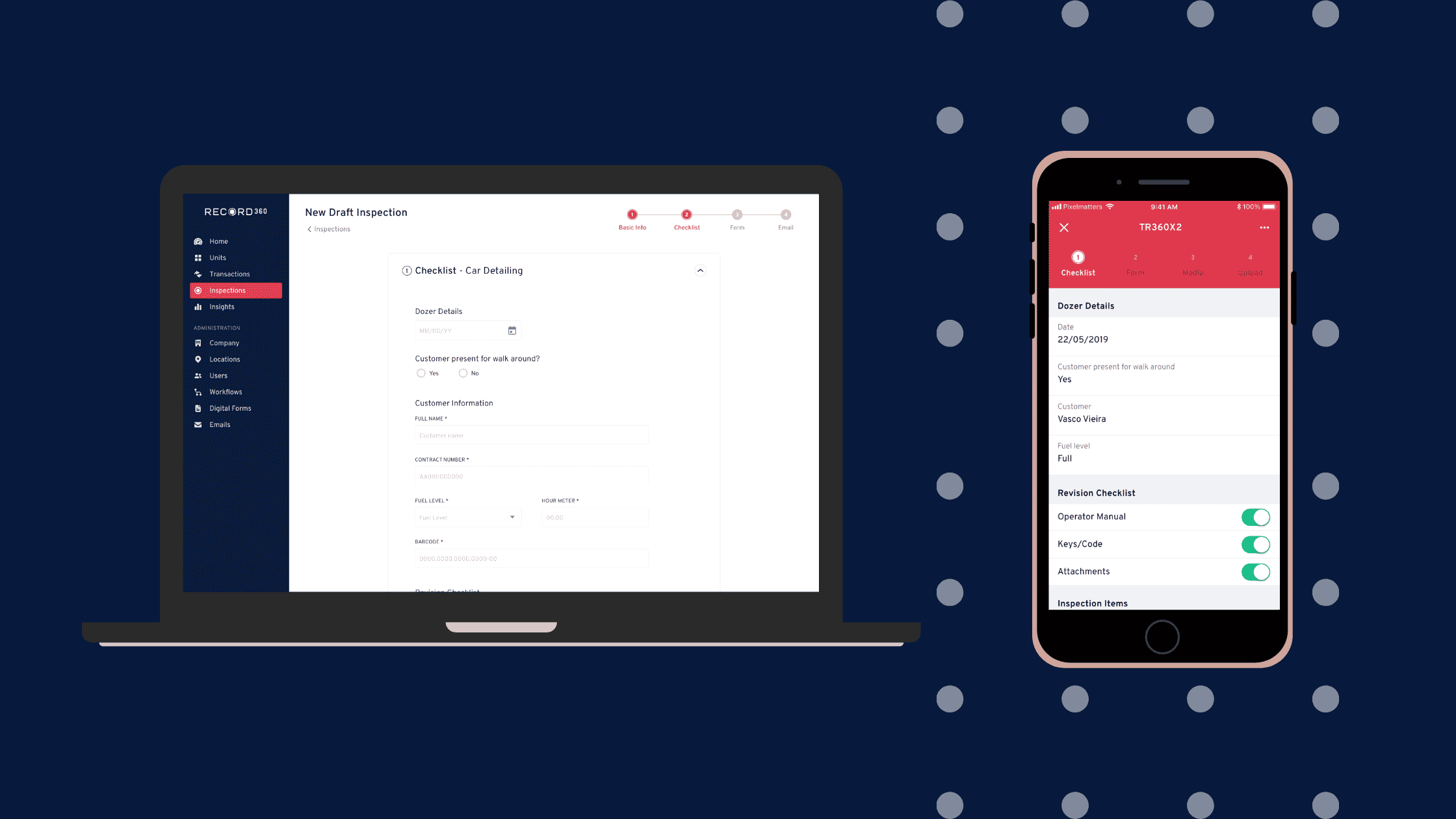

5. Inefficient truck inspection implementation

Conventional inspection systems are often inefficient, whether using hand-drawn and narrative condition descriptions, relaying printed damage reports on office tables and bulletins, or others.

All this internal inefficiency in your truck inspection workflows could result in fewer rentals deployed, delayed service delivery, lagging rental and inspection schedules, etc.

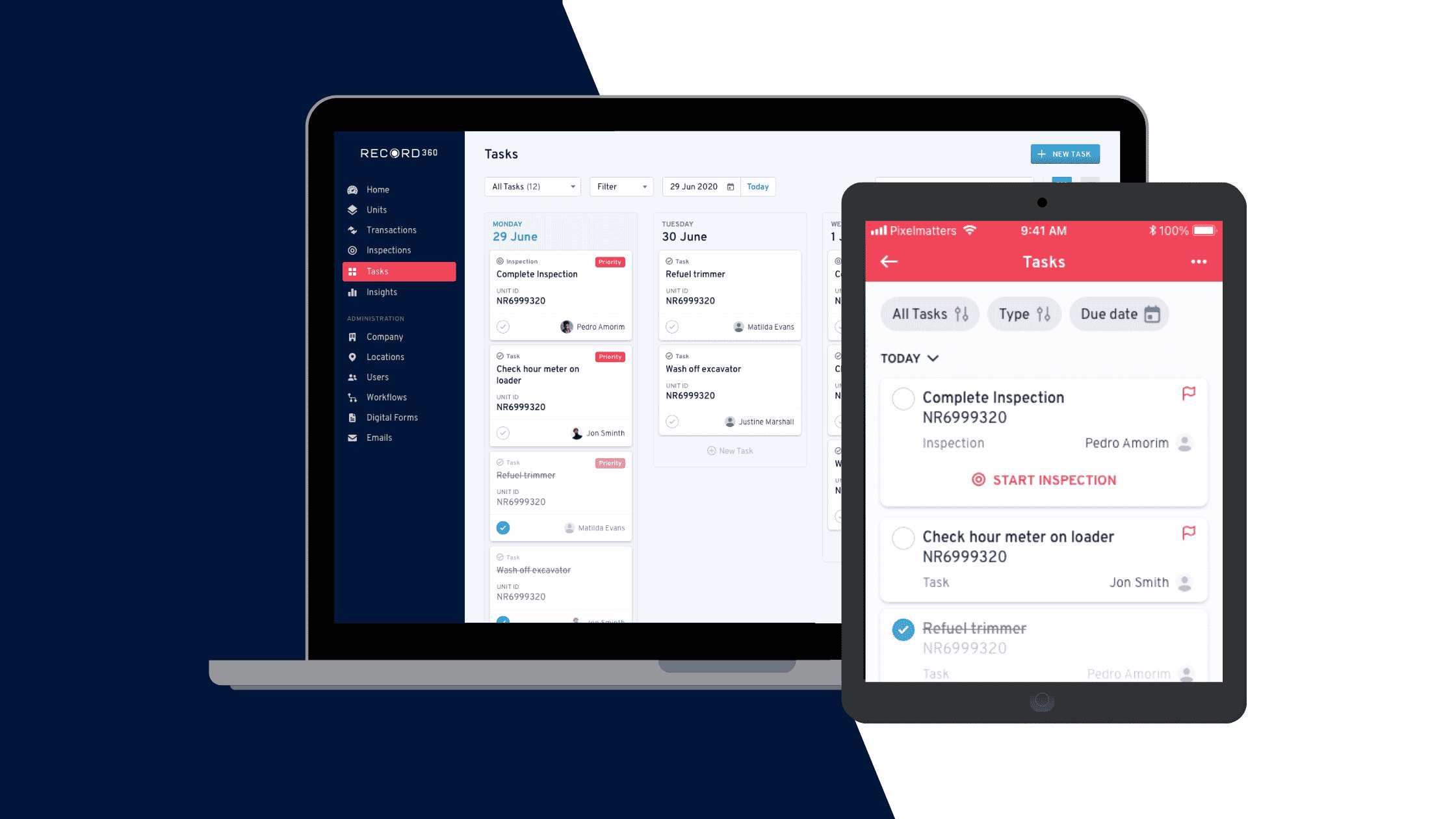

Streamline your inspection workflow management by digitizing related processes, forms, and assignments for your team. Our Record360 truck inspection app can help with that.

For one, it allows you to start an inspection with your customized in-app checklist, then send it to your team. This enables technicians to complete a request immediately in the field, saving plenty of working time.

Record360 also makes it quicker for you and your team to begin inspections and document your vehicle’s condition.

Under the “New Inspection” functionality, Record360 displays various task choices. Clicking on any one of them leads you to the right forms, checklists, etc., suited to the type of inspection you need to perform. This simplifies and accelerates your team’s work.

When you can perform and finish inspections fast and correctly, you boost your internal productivity, service delivery, and customer experience.

6. Disregard a roadway safety mindset

The ultimate reason you conduct truck inspections is to promote roadway safety, which involves your clients’ lives, vehicles, and even national properties, among others.

Which is why you should always keep that in mind when inspecting your fleet. The goal of guaranteeing safety motivates you to examine trucks extensively — even beyond what’s in the checklist, routine, or other minimum requirements.

Inculcate this roadway safety mindset and culture among your team, so they can also give their best during truck inspections.

Stop committing these commercial truck inspection mistakes.

As a truck rental company, you c-a-n-n-o-t afford to compromise on your vehicle inspections.

Doing so endangers your clients, fleet assets, and eventually, your business.

Avoid making these and other truck inspection mistakes — and you’ll reap the benefits of managing a safety-first rental business.

Interested in learning more about Record360? Schedule a demonstration today.