The Department of Transportation (DOT) has a few rules for commercial motor vehicle drivers. Sometimes, it’s hard to tell when you’ll get surprise roadside inspections, so making a pre-trip inspection yourself will help you stay compliant and safe while driving.

DOT inspections involve different factors that we’ll analyze in this post. If you want to be ready for any roadside inspection or are simply looking to meet DOT standards, keep reading!

The Essentials of DOT Inspections

DOT inspections are different “assessments” that allow experts to determine whether a commercial vehicle is in good working condition. They are conducted on any CMV over 10,000 lbs.

The goal of these inspections (in addition to assessing the condition of your vehicle) is to keep the road safe for everyone.

Undoubtedly, any accident involving heavy-duty vehicles can be fatal, which is why the Department of Transportation took its measures seriously.

According to the CVSA, about 4 million inspections are conducted annually throughout North America.

Some of the agents allowed to perform these inspections include:

- Federal Motor Carrier Safety Administration (FMCSA)

- Commercial Vehicle Safety Alliance (CVSA)

- State Troopers

These inspections can happen in different locations, including:

- Truck Stops

- Weigh Stations

- Carrier Locations

- Roads

Something crucial to keep in mind is that there are seven DOT inspection levels:

- Level I – North American Standard Inspection

- Level II – Walk-Around Vehicle Inspection

- Level III – Driver-only Inspection

- Level IV – Special Inspection

- Level V – Vehicle-only Inspection

- Level VI – Enhanced NSA Inspection for Radioactive Shipments (for vehicles transporting highway route-controlled quantities of radioactive materials)

- Level VII – Jurisdictional Mandated Commercial Vehicle Inspection

The most common scenarios involve the Level I inspections. The inspector will analyze different documents, including driver credentials, vehicle documentation, and more.

On the other hand, the inspection process of the truck itself involves different parts such as the brake systems, coupling devices, steering mechanisms, tractor protection valve system, etc.

How to Ensure You Comply with DOT Regulations

The best way to ensure DOT compliance is to prepare. There are a few tips we can give you to ensure a smooth inspection process:

- Clean your internal and external vehicle components.

- Consider the DVIR inspection checklist.

- Create an efficient preventive maintenance strategy for your fleet.

- Secure your cargo correctly.

- Consider digitizing your inspection process with advanced software.

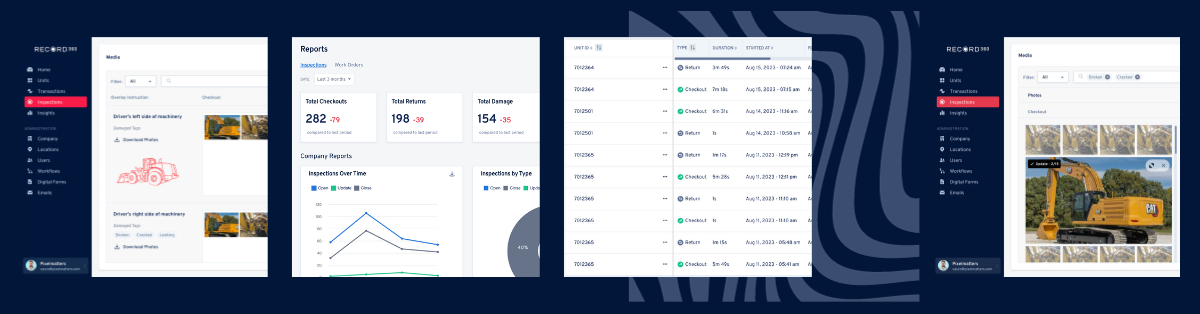

Record360 allows you to inspect your trucks thoroughly and promote a safer driving experience. Its comprehensive reporting features also help you ensure you have all the documentation for your next inspection, including lease agreements, vehicle registration documents, shipping papers, and more.

When you inspect your truck with advanced software, you can avoid common DOT violations, which include:

- Electronic Logging Device (ELD) mandate violations

- Invalid commercial driver’s license

- Going over mandated HOS

- Missing proof of inspections

- Having faulty lights

- Improperly secured cargo

Must Read: Mastering Safety: The Importance of Motor Carrier Compliance

Bottom Line – Keep Your Next Journey Stress-Free

In many scenarios, a DOT inspection may surprise the driver. If you want to secure the integrity of your commercial vehicles, you should create an inspection report yourself before taking the truck outside.

Using software like Record360 ensures you can stay safe by implementing a thorough inspection whenever you need one. It allows you to create reports with detailed information, photos, videos, and annotations, which will help you prepare for your next DOT inspection.

As long as you comply with regulations, you will keep all your journeys safe and stress-free.

To learn more, contact Record360 today!