We all know that construction equipment is the lifeblood of any building project. Whether you’re constructing a skyscraper or renovating a house, having reliable machinery is a must. But here’s the thing: these heavy-duty machines need some TLC too. That’s why we’re here with some pro tips on how to inspect your construction equipment like a boss.

Alright, let’s get down to business. Construction gear is a big deal, and keeping it in tip-top shape is crucial. We’re here to show you the ropes when it comes to inspecting your construction equipment like a pro.

Why Checking Your Equipment Matters

Why bother with all this checking? Well, these machines go through a lot of wear and tear. Regular inspections can spot potential problems, avoid accidents, and save you a ton of downtime and cash.

Before You Start: Pre-Operation Inspection

Why It’s Important

First things first: before you rev up that engine, give your machine a once-over. It’s like a health check for your equipment.

What to Check

- Look for any leaks, loose bits, or damage.

- Check fluid levels—oil, coolant, hydraulic fluid.

- Ensure all safety features are a go, including lights and alarms.

Daily Checkup: Your Equipment’s Daily Inspection Routine

Doing a quick daily check keeps your equipment happy and healthy. It’s like brushing your teeth but for machines.

What to Look Out For

During these daily checkups, keep an eye out for:

- Weird sounds or vibrations

- Any fluid leaks

- Tires acting funky

- Dashboard warning lights trying to grab your attention

Making it a Daily Habit

Set up a routine for these daily inspections. Do ’em before and after each shift. It’ll soon become second nature.

Regular TLC: Maintenance is Key

Daily checks are great, but don’t forget about regular maintenance. It’s like giving your machine a spa day.

Setting Up a Maintenance Schedule

Create a schedule for maintenance tasks—things like oil changes and filter replacements.

Why Regular Maintenance Rocks

Regular TLC keeps your equipment humming smoothly, and it’s way cheaper than surprise repairs.

Specialized Care: Equipment-Specific Checks

Different equipment, different checks. Makes sense, right? We’ll break it down for you.

Tailored Inspections

Excavators, bulldozers, cranes—they all have their quirks. Get to know your equipment and tailor your inspections accordingly.

Special Considerations

Think about the environment your equipment works in. Extreme temperatures or corrosive materials? Factor that into your inspections.

Safety First: Keeping Everyone Safe

Safety should be your top priority. Regular checks play a huge role in keeping your worksite secure.

Protecting Your Team

Well-maintained equipment is less likely to go haywire, which means fewer risks for your crew.

Accident Prevention

Spotting potential hazards during inspections can save lives and prevent costly accidents.

Going High-Tech: Advanced Inspection Tricks

Embrace technology—it’s your friend. We’ll show you how to use it wisely.

Embracing Technology

Consider using software and sensors for real-time equipment monitoring. It’s like having an extra set of eyes.

When to Call in the Pros

Sometimes, you need the big guns. Hire professional inspectors now and then for a thorough evaluation.

Paper Trail: Keeping Records

Documenting your inspections is a must. It’s like keeping a diary for your equipment.

Why Documentation is Vital

Keep records of all inspections, repairs, and maintenance tasks. It’s handy for tracking your equipment’s history.

Using Data to Make Decisions

Take a close look at your inspection data. It can help you make smart decisions about repairs, replacements, or upgrades.

Common Gremlins and How to Beat Them

Learn to recognize the usual suspects—common equipment problems—and how to kick ’em to the curb.

Recognizing Common Issues

Keep an eye out for things like hydraulic leaks, overheating, or electrical glitches.

Troubleshooting Like a Pro

If you spot a problem, consult your equipment manual or seek advice from the experts. You got this!

Why Bother: Benefits of Regular Checks

In a nutshell, regular equipment checks mean:

- Safer operations

- Less downtime

- Longer equipment life

- Lower maintenance costs

By making inspections a part of your routine, you’re set for smoother sailing on your construction projects.

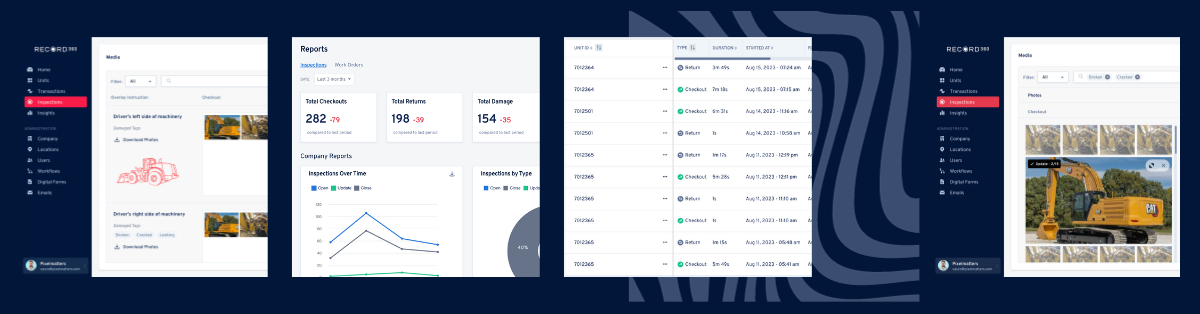

A Smoother Ride with Record360

Want to take your construction equipment inspections to the next level? Consider using Record360, the ultimate tool for hassle-free equipment tracking and inspections. With Record360, you can simplify your inspection process, improve record-keeping, and ensure your equipment is always in peak condition. Try it today and experience the difference!

Conclusion

Checking your construction equipment isn’t just a chore; it’s a smart move. Keep your machinery in top shape, and your projects will thank you.